Fleet management cost analysis is the process of evaluating and breaking down the various expenses associated with operating a fleet from fuel and maintenance to labor, route efficiency, and vehicle utilization. By closely analyzing these components, fleet managers gain valuable insights into where resources are being overused, underutilized, or misallocated.

The need for cost analysis is growing as fleet costs continue to rise. Industry-wide, businesses are facing increased fuel prices, driver shortages, vehicle maintenance delays, and stricter regulatory requirements. These challenges make it more difficult to maintain profit margins, especially for small to mid-sized trucking companies that operate on lean budgets.

That’s why more fleet managers are turning to data-driven strategies like route optimization to take control of their expenses. By strategically planning and adjusting truck routes, companies can reduce fleet expenses, improve delivery timelines, and minimize fuel usage, all while maintaining service quality.

This article examines key strategies for conducting effective fleet management cost analysis and implementing practical changes that reduce costs and enhance overall operational efficiency.

What is Fleet Management Cost Analysis?

Fleet management cost analysis goes beyond simply tracking expenses; it’s about understanding the true cost of operating a fleet and using that data to drive smarter decisions. A comprehensive analysis provides the foundation for identifying inefficiencies, setting realistic cost-saving goals, and implementing actionable strategies to optimize operations.

Key Components of Fleet Costs

To perform effective cost analysis, it’s essential to understand the primary cost categories that impact your fleet’s bottom line:

- Fuel: Often the largest single operating cost. Inefficient routes, idling, and poor driving habits can drastically increase consumption.

- Maintenance and Repairs: Includes both scheduled maintenance and unexpected breakdowns. Delayed maintenance can lead to costly repairs and vehicle downtime.

- Labor Costs: Driver wages, overtime, benefits, and administrative costs associated with dispatch and support staff.

- Tolls and Compliance Fees: Vary by route and region, but can add up quickly if not factored into trip planning.

- Vehicle Downtime: Lost revenue and increased expenses when vehicles are out of service, whether due to breakdowns or inefficient scheduling.

- Insurance and Depreciation: While fixed, these costs still impact long-term profitability and must be accounted for in any cost analysis.

Each of these components contributes to the total cost per mile or cost per vehicle two metrics that are essential for comparing performance over time or across your fleet.

Why Ongoing Cost Analysis is Crucial

Fleet operations are dynamic. Fuel prices fluctuate, routes change, new regulations arise, and equipment ages. A one-time analysis won’t give you the insights needed to stay competitive. Ongoing cost analysis allows fleet managers to:

- Respond quickly to rising costs or inefficiencies

- Track progress on cost-reduction initiatives

- Benchmark performance across vehicles, drivers, or locations

- Forecast budgets more accurately

By making cost analysis a regular part of fleet operations, managers can adjust strategies before small issues become major expenses.

Supporting Smart Goals for Fleet Managers

Effective cost analysis also supports the creation of smart goals for fleet managers objectives that are Specific, Measurable, Achievable, Relevant, and Time-bound. For example:

- Specific: Reduce fuel costs by improving route efficiency.

- Measurable: Lower fuel spend by 10% in Q4.

- Achievable: Use GPS and telematics data to identify better routes.

- Relevant: Directly tied to reducing overall fleet costs.

- Time-bound: Achieve results within a three-month period.

With accurate cost data, fleet managers can set goals that are not only realistic but also impactful, guiding better decision-making and aligning teams around clear, measurable outcomes.

Common Contributors to High Fleet Costs

Understanding what drives up fleet costs is the first step in reducing them. While some expenses are unavoidable, many operational inefficiencies go unnoticed until they significantly impact your bottom line. Below are some of the most common cost drivers that fleet managers should monitor closely.

Inefficient Routing and Unnecessary Mileage

Poorly planned routes are one of the most direct causes of inflated operational costs. When trucks travel longer distances than necessary or get stuck in traffic-heavy areas, fuel usage increases and delivery times suffer. Even minor inefficiencies like overlapping routes or missed opportunities for load consolidation can add up quickly when multiplied across an entire fleet.

Implementing route optimization software and real-time traffic monitoring can help ensure every mile driven is necessary and efficient. This not only reduces fuel consumption but also lowers wear and tear on vehicles and improves driver productivity.

Vehicle Idling and Underutilization

Excessive idling is a silent profit killer. It wastes fuel, contributes to engine wear, and can skew performance metrics. Many fleets lose thousands of dollars annually simply because engines are left running when vehicles are stationary.

Underutilized vehicles those that are not regularly dispatched or carry less-than-optimal loads also drive up costs by taking up space, requiring maintenance, and depreciating in value without generating sufficient revenue.

To address this, fleet managers should:

- Monitor idle time with telematics systems

- Set and enforce idling policies

- Review vehicle usage reports regularly

- Rotate vehicles to balance wear and extend asset life

Lack of Data Tracking or Outdated Systems

Running a modern fleet without modern tools can severely limit operational efficiency. Relying on paper logs, manual reporting, or outdated spreadsheets often leads to errors, delays, and missed cost-saving opportunities.

Without real-time data, fleet managers may struggle to:

- Identify high-cost routes or vehicles

- Spot trends in fuel consumption or maintenance needs

- Respond proactively to compliance issues

Adopting a fleet management system that centralizes data and provides reporting tools is essential for conducting timely and accurate cost analyses.

Poor Maintenance Planning and Increased Downtime

Reactive maintenance, or fixing things only when they break, is one of the most expensive ways to manage a fleet. It results in unexpected vehicle downtime, missed deliveries, emergency repair costs, and sometimes even regulatory fines.

In contrast, preventive maintenance helps reduce long-term expenses by extending the vehicle’s life and catching problems before they escalate. Without a structured maintenance plan, fleets are more vulnerable to costly disruptions.

Fleet managers should:

- Use digital maintenance schedules to track service intervals

- Automate reminders for inspections and oil changes

- Analyze repair trends to plan ahead for major service needs

Route Optimization as a Cost-Cutting Strategy

As fleet operating costs continue to climb, route optimization has emerged as one of the most effective ways to cut unnecessary spending. By strategically planning the most efficient paths for deliveries, pickups, and vehicle movement, fleet managers can significantly reduce expenses while improving service quality.

Benefits of Optimized Truck Routing

Route optimization doesn’t just trim miles off the map it drives measurable improvements across multiple cost areas. The following are key financial and operational benefits:

Reduced Fuel Consumption

Fuel is often the largest variable expense in fleet operations. Taking longer or congested routes, even by a small margin, can result in thousands of dollars in excess fuel costs annually. Optimized routing ensures that every trip is planned with fuel efficiency in mind reducing idling, avoiding traffic-heavy areas, and eliminating backtracking.

Shorter Delivery Times

When routes are planned with precision, drivers spend less time navigating inefficient paths and more time completing deliveries. This leads to improved customer satisfaction and more completed jobs per shift. Over time, faster routes also help reduce wear and tear on vehicles, which contributes to lower maintenance expenses.

Fewer Overtime Hours

Poor routing often leads to longer drive times and unpredictable delays, resulting in costly overtime. With optimized routes, drivers complete their work within scheduled hours more consistently, helping reduce labor costs and avoid burnout from overextended shifts.

Tools and Technologies That Support Route Optimization

Fleet managers have more tools than ever before to help refine their routes and control costs. The right technology enables easier adaptation to real-world conditions in real-time, leveraging historical data to inform smarter decisions over time.

GPS Tracking

GPS tracking provides real-time location data, helping dispatchers monitor vehicle positions and adjust routes based on traffic, road closures, or delivery urgency. This technology also helps verify driver activity and ensures that planned routes are being followed.

Route Planning Software

Advanced route planning platforms use algorithms to determine the most efficient order of stops, taking into account variables like traffic conditions, delivery time windows, fuel stops, and vehicle capacity. Many tools also offer route simulations, allowing managers to forecast potential savings before changes are implemented.

Telematics

Telematics systems collect data on vehicle performance, driver behavior, fuel usage, and trip history. By analyzing this information, fleet managers can identify inefficiencies, such as unnecessary detours or frequent stops, and adjust routing strategies accordingly. Telematics also integrates with maintenance schedules to ensure vehicles remain road-ready.

Smart Goals for Fleet Managers: Setting the Right Objectives

Establishing clear, measurable goals is essential for turning fleet cost analysis into actionable results. Without defined objectives, even the most detailed reports and data insights can fall flat. That’s where SMART goals Specific, Measurable, Achievable, Relevant, and Time-bound come into play.

Examples of SMART Goals for Fleet Managers

SMART goals help fleet managers translate data into real-world improvements. These goals should directly address cost-saving opportunities uncovered through analysis and should be easy to track over time.

Here are a few examples:

- Specific: Decrease idle time across the fleet.

- Measurable: Cut idle time by 20% by the end of Q2.

- Achievable: Use telematics to monitor idle time and train drivers accordingly.

- Relevant: Aligns with the goal of reducing fuel waste and improving efficiency.

- Time-bound: Implement changes and measure results within 90 days.

Other SMART goal examples include:

- Reduce total fuel costs by 10% over the next six months by optimizing routes and enforcing idling policies.

- Improve on-time delivery rates by 15% by Q1 through better route planning and GPS tracking.

- Lower maintenance-related downtime by 8% this fiscal year using a preventative maintenance schedule.

Aligning Cost Analysis with Operational Benchmarks

Once goals are set, they need to be supported by meaningful benchmarks. These benchmarks help you track progress and compare performance across time, vehicles, or locations. Without them, it’s difficult to know whether cost-cutting strategies are truly effective.

Operational benchmarks to guide SMART goals may include:

- Average fuel cost per vehicle per month

- Average delivery completion time

- Number of maintenance incidents per 10,000 miles

- Driver compliance rates with assigned routes and schedules

Aligning these data points with your fleet management cost analysis allows you to fine-tune your approach and pivot quickly when goals aren’t being met.

Monitoring KPIs that Impact Fleet Expenses

Key performance indicators (KPIs) give you the tools to monitor whether your goals are on track. These metrics should be reviewed consistently weekly, monthly, or quarterly to help you stay agile in decision-making.

Important KPIs include:

- Cost per mile: Tracks how much it costs to operate each vehicle per mile driven, factoring in fuel, labor, maintenance, and other overhead.

- Fuel efficiency (MPG): Highlights trends in driver behavior, vehicle health, and route planning efficiency.

- On-time delivery rate: Measures how well your routing and dispatch systems are performing.

- Idle time per driver or vehicle: Offers insight into fuel waste and potential mechanical strain.

- Maintenance cost per vehicle: Helps forecast future costs and identify equipment that may be underperforming.

When these KPIs are monitored in tandem with smart goal-setting and cost analysis, fleet managers are well-positioned to make data-driven decisions that lower expenses and improve operational performance.

Practical Tips to Reduce Truck Fleet Costs

While technology and analytics provide the foundation for cost control, real-world strategies and day-to-day practices are just as essential. Fleet managers can take several proactive steps to reduce truck fleet costs and boost overall efficiency.

Analyze and Adjust Routes Frequently

Route optimization should never be a one-time setup. Traffic patterns, fuel prices, customer delivery windows, and weather conditions are constantly changing so your routing should, too.

By regularly reviewing and adjusting routes based on:

- Traffic congestion and construction updates

- Fuel station locations with the best pricing

- Delivery time windows and customer preferences

you can reduce unnecessary mileage, improve delivery reliability, and cut fuel waste. Frequent route analysis also helps avoid repeated inefficiencies and ensures your fleet is adapting to current conditions.

Implement Preventative Maintenance Schedules

Waiting for a breakdown before taking a truck into the shop can be one of the most expensive mistakes in fleet operations. Emergency repairs typically cost more, extend downtime, and disrupt schedules.

A preventative maintenance program allows you to:

- Address minor issues before they become major failures

- Extend vehicle lifespan

- Improve fuel efficiency through regular tune-ups

Set up automated reminders for oil changes, inspections, tire rotations, and brake checks. Digital maintenance logs can help you track trends and forecast service needs.

Train Drivers on Fuel-Efficient Driving Habits

Driver behavior has a direct and often underestimated impact on fleet costs. Simple changes in how vehicles are operated can lead to measurable savings in fuel and maintenance.

Areas to focus on during training include:

- Reducing excessive idling

- Avoiding aggressive acceleration and braking

- Maintaining steady speeds on highways

- Using cruise control and gear optimization where applicable

Incentivizing drivers with performance bonuses tied to fuel efficiency and safety metrics can reinforce good habits and build a more cost-conscious culture.

Review and Renegotiate Supplier and Fuel Contracts

As your fleet grows or your routes change, it’s important to revisit the agreements you have with fuel providers, maintenance vendors, and parts suppliers.

Regularly reviewing these contracts allows you to:

- Negotiate bulk discounts or loyalty rewards

- Identify better regional suppliers based on route geography

- Ensure terms still align with your current operational volume

Don’t hesitate to shop around loyalty is valuable, but so is cost savings.

Use Data from Cost Analysis to Eliminate Inefficiencies

Fleet management cost analysis is only as effective as the action it inspires. With access to accurate cost data, you can pinpoint the exact sources of inefficiency within your operations.

Examples of data-driven decisions include:

- Retiring high-maintenance vehicles that exceed their cost-per-mile threshold

- Consolidating routes with low delivery density

- Adjusting dispatch strategies to better match load demand

Use reports and KPIs to guide your next steps, validate your strategies, and demonstrate cost improvements to stakeholders. Making decisions based on real data, not assumptions, is one of the most powerful ways to reduce fleet expenses over time.

Case Example: How Route Optimization Cut Fleet Costs for a Regional Carrier

To illustrate the real-world impact of fleet management cost analysis and route optimization, let’s consider a fictional but highly realistic scenario involving a mid-sized regional trucking company.

Background: Rising Costs and Operational Gaps

Silverline Logistics, a regional carrier operating 85 trucks across five states in the Midwest, was experiencing a steady increase in fuel costs and overtime pay. Their cost-per-mile had risen by 12% over the past two quarters, largely due to inefficient dispatching, overlapping delivery zones, and lack of real-time traffic data.

Despite having capable drivers and quality equipment, the fleet manager lacked visibility into daily route performance and was relying on outdated planning methods based on static maps and spreadsheets.

The Approach: Implementing Route Optimization

After conducting a fleet management cost analysis, the company identified route inefficiencies as a major cost driver. They decided to invest in an integrated route planning and telematics system that could:

- Analyze historical trip data

- Provide real-time traffic and weather updates

- Automate route assignments based on delivery time windows and vehicle capacity

- Track driver compliance with assigned routes

They also retrained dispatchers and drivers on the new system and integrated the platform with their maintenance scheduling tool to anticipate service needs based on mileage.

The Results: Measurable Cost Reductions

Within the first 90 days, the company saw significant improvements:

- Fuel costs dropped by 14%, thanks to shorter routes and reduced idling

- On-time delivery rate increased from 84% to 95%

- Driver overtime hours were cut in half, reducing payroll expenses by $6,000 per month

- Maintenance issues declined, as smoother routing led to less wear and tear on equipment

The company also discovered that three of their older trucks were consistently underperforming and consuming more fuel. Based on their cost-per-mile data, they replaced them with newer, more efficient models further boosting fuel economy.

Lessons Learned

Silverline Logistics’ case highlights a few key takeaways:

- Data-driven routing decisions make a measurable impact on fuel, labor, and maintenance costs

- Technology adoption pays for itself quickly when aligned with specific cost-reduction goals

- Ongoing analysis is necessary to ensure continued performance improvements and cost control

This example echoes the real successes many fleet operators are achieving today by applying modern route optimization tools in combination with a proactive cost analysis strategy.

Frequently Asked Questions (FAQ)

What is fleet management cost analysis?

Fleet management cost analysis is the process of evaluating all operational expenses associated with managing a fleet, such as fuel, maintenance, labor, route efficiency, and vehicle utilization, to identify inefficiencies and areas for cost savings.

Why is cost analysis important for fleet operations?

Without ongoing cost analysis, fleet managers risk overspending, underutilizing resources, and missing opportunities to streamline operations. Analyzing costs allows for data-driven decisions that improve efficiency and reduce unnecessary expenses.

How does route optimization reduce fleet costs?

Route optimization helps fleets save money by reducing mileage, fuel consumption, idle time, and overtime. By selecting the most efficient paths for deliveries and pickups, companies improve delivery times and minimize wear and tear on vehicles.

What are the main KPIs to track in fleet cost analysis?

Key performance indicators (KPIs) that help monitor fleet efficiency include:

- Cost per mile

- Fuel efficiency (MPG)

- On-time delivery rate

- Vehicle downtime

- Idle time

- Maintenance cost per vehicle

How often should fleet cost analysis be done?

Ideally, fleet cost analysis should be conducted monthly or quarterly, depending on the size of your operation. This allows managers to stay proactive and make timely adjustments before small issues escalate into costly problems.

Can small fleets benefit from cost analysis and optimization?

Absolutely. While large fleets may see a bigger total dollar savings, small and mid-sized fleets often see a higher percentage reduction in costs by implementing even basic strategies like preventative maintenance, fuel monitoring, and route planning.

What tools help with cost analysis and optimization?

Helpful tools include:

- GPS tracking systems

- Telematics software

- Route planning and dispatch platforms

- Fleet management systems that track fuel, maintenance, and driver behavior

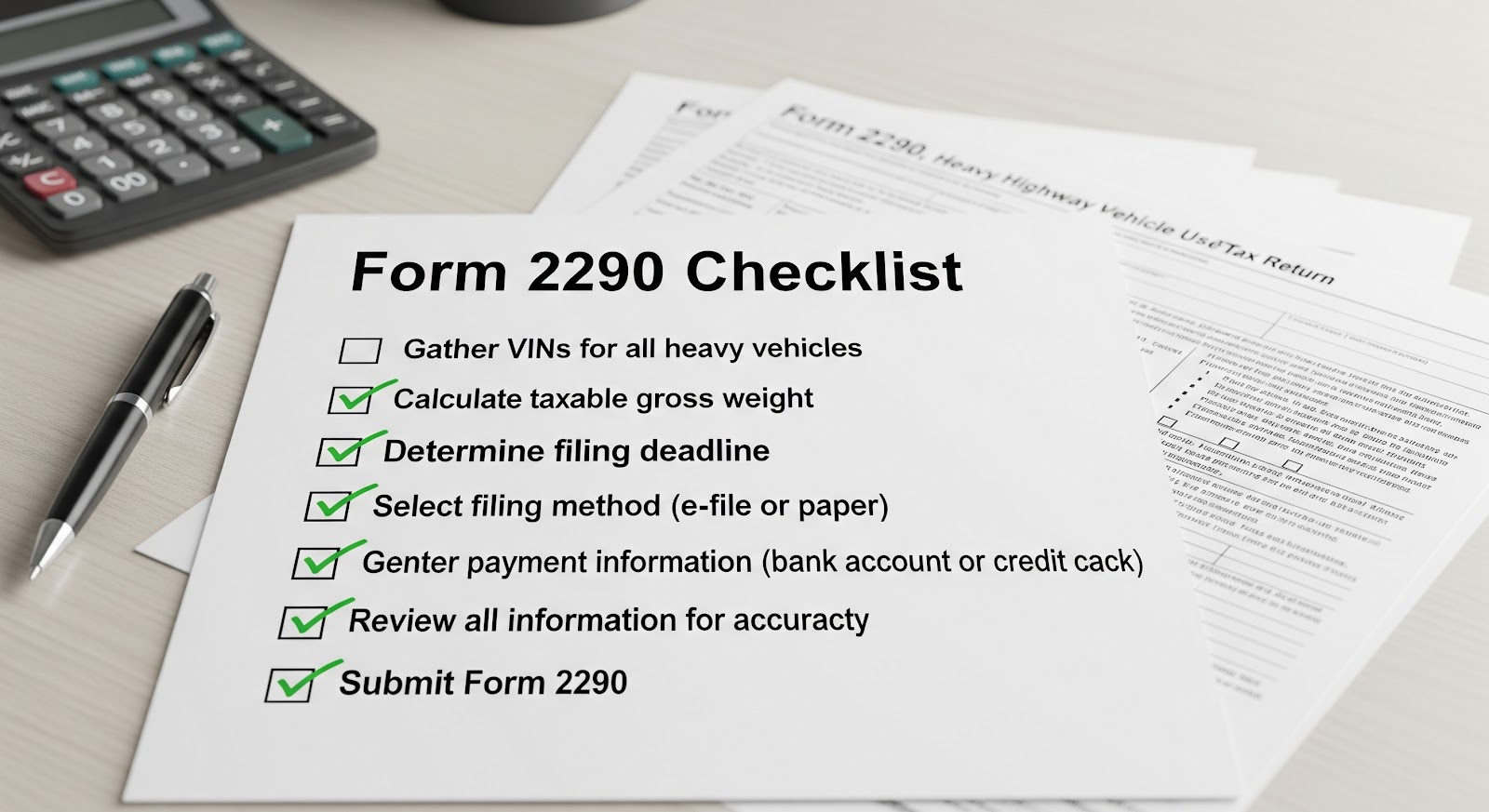

How can ExpressTruckTax support my fleet management goals?

While ExpressTruckTax specializes in helping carriers file Form 2290, VIN corrections, and 2290 amendments, the platform also helps streamline your compliance process. With that burden off your plate, you can focus on more strategic aspects of your operation, like cost control and optimization.